Water-Source Heat Pumps (WSHP) - The Energy-Efficient HVAC Solution

What is a Water-Source Heat Pump (WSHP)?

A WSHP HVAC unit heats or cools air using the heat pump direct expansion (DX) cycle in which the refrigerant in the refrigeration circuit exchanges heat with water. The water serving the unit is typically connected to a water loop, in which the water may be heated by a boiler or cooled by a cooling tower, depending on the mode of operation.

A heat pump is comparable in efficiency in cooling mode with other DX equipment, but improved efficiency can be seen when in heating mode. When multiple WSHPs are connected to a single water loop this efficiency is further enhanced because heat can be transferred between units decreasing or eliminating the need to operate the boiler or cooling tower. This is also known as a heat recovery loop. For this reason, WSHPs are an excellent solution in commercial HVAC applications especially as the industry progresses towards electrification.

Need assistance?

Your local AAON rep is ready to help.

👉 Find a Rep

How Does a Water-Source Heat Pump Work?

A water-source heat pump contains a refrigeration cycle and is connected to a water loop in which the refrigerant exchanges heat with the water. The five main components of a water-source heat pump consist of the following:

-

Compressor - pumps refrigerant in and throughout the copper piping in the unit.

-

Air-to-refrigerant heat exchanger - also known as the indoor coil, air passes over and exchanges heat with the refrigerant inside.

-

Expansion valve - regulates the amount of refrigerant entering the evaporator.

-

Water-to-air heat exchanger - a "coaxial coil" in which there are two concentric tubes wrapped in a coil. The inner tube carries the refrigerant while the outside tube contains water allowing a temperature exchange between mediums.

-

Reversing valve - enables the unit to switch between heating mode and cooling mode based on demand.

A water-source heat pump also contains a supply fan in addition to the components of the DX cycle and a reversing valve that is used to switch from heating to cooling mode. In cooling mode, this fan moves the air from the space over the cool air-to-refrigerant heat exchanger contained in the unit. The cool refrigerant absorbs the heat from the air, resulting in cooler supply air that is distributed to maintain space conditions. The heat that was transferred from the air to the refrigerant is then expelled into the water loop via the coaxial coil.

Cooling Cycle of a Water-Source Heat Pump

When heating is needed from the unit, the heat exchangers in the unit switch roles by using a reversing valve to reverse the refrigerant flow direction. The water-to-refrigerant coaxial coil now extracts heat from the water and the air-to-refrigerant heat exchanger transfers heat to the supply air as it passes over it.

Heating Cycle of a Water-Source Heat

The purpose of the water connection to the unit is to simply allow the refrigerant cycle the opportunity to absorb or reject heat during the heating or cooling process. Since the refrigerant cycle is doing the heating and cooling, the water temperature simply has to be within a range capable of accepting or rejecting heat which is normally between 60˚F to 90˚F. In the heating season, a boiler can be used to ensure the water temperature does not go below 60˚F. In the cooling season, a cooling tower can be used to keep the water temperature below 90˚F. This means that neither the boiler nor the cooling tower has to operate as long as the water temperature is within this acceptable range (60˚F to 90˚F).

The advantages associated with the high efficiency and reduced energy usage of a WSHP system can be attributed to:

-

The circulating pumps for the water loop do not have to run at full capacity a good portion of the time.

-

The boiler(s) and cooling tower(s) operate less than in a traditional hydronic system.

-

When multiple WSHPs are connected together by the heat pump water loop, it is not uncommon during the shoulder seasons (between heating and cooling extremes) for some heat pumps to operate in heating while others are cooling. This allows for excess heat contributed to the loop from one WSHP operating in cooling to be offset by another WSHP operating in heating. The result is extended periods of time with the loop temperature remaining in the acceptable range of 60˚F to 90˚F without the boiler or the cooling tower operating.

Thermal Energy Conservation with WSHPs

Types of Water-Source Heat Pump Systems

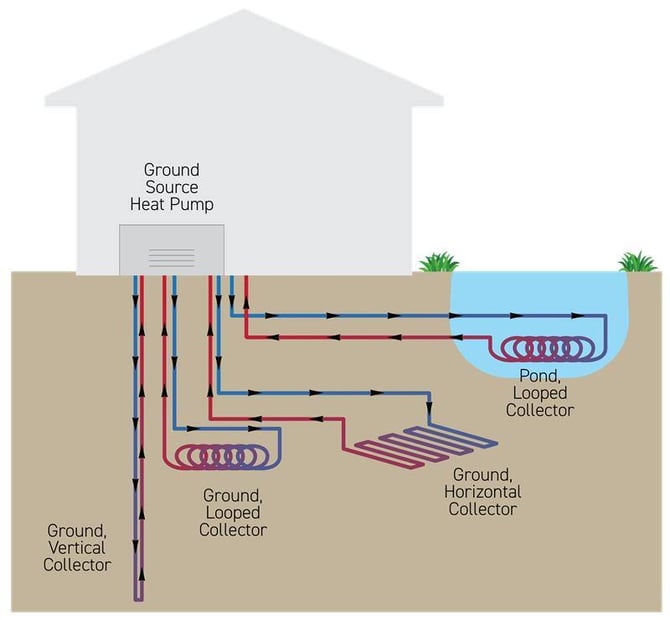

Although the designation of WSHP is usually reserved for systems that incorporate boilers and cooling towers, the ground-source heat pump, commonly referred to as a geothermal heat pump, also uses a water loop to absorb and reject heat. Instead of a boiler and a cooling tower, a ground-source heat pump utilizes long lengths of water piping routed in the ground. These are arranged in a series of vertically or horizontally installed pipe loops called ground bores. Ground temperatures in the U.S. typically range between 50°F to 65°F. To take advantage of these ground temperatures, these water pipe systems ensure the water temperature range is modified between 35˚F to 90˚F. When the water temperature drops below ground temperature in the heating season, the ground warms the water. In the cooling season when the water temperature is higher than the ground temperature, the ground absorb the heat from the water. Significant energy savings are achieved using this system by not having to operate a boiler or a cooling tower.

For units that take on large cooling loads, a ground source unit can still be utilized. Although traditional ground loops utilize the heat transfer from the soil, and open loop system can also be used. An open loop system draws groundwater or surface water from a well, lake, pond or river and uses that as the heat transfer medium through the heat pump. The rejected heat is discharged back to the source or another area. This system yields higher efficiency in thermal energy transfer, but can be hard to maintain due to concerns with debris and pollutants in the water. Water quality must be monitored closely in this configuration. Today, these systems are nearly always closed loop systems to conform with regulations developed to protect the environment and natural resources. In the past open loop systems that used surface water (a lake, a pond, or a river) or water extracted from the ground, were used but these are rarely applied in new applications today."

Ground-source Water Loop Configurations

Cost and land area are the primary deterrents for building owners when considering a ground source heat pump system. The drilling of a bore field is relatively expensive when compared to the components of a traditional WSHPs. Although a higher initial cost, the energy savings over time not only pay for this initial investment, but will continue accruing savings over the life of the system. In locations where space and budget are limited, hybrid installations are possible. Hybrid installations allow for a smaller bore field by incorporating a boiler and/or cooling tower to supplement the system capacity.

Benefits of Using WSHP in HVAC

WSHP systems have many advantages when compared to other HVAC systems. WSHP systems are ideal for a variety of applications including office buildings, hotels, schools, and hospitality. Of the many advantages, the most outstanding relates to energy. A WSHP system can easily be designed to only use electricity as its fuel source. This is especially important for applications using renewable energy sources or prioritizing electrification and decarbonization in their HVAC design. Besides being all-electric, WSHPs contribute to sustainability efforts by being especially efficient and consuming less energy especially when heating compared to other equipment.

Another energy saving attribute occurs when multiple WSHPs are connected to a common water loop. Units operating in both cooling and in heating using common loop water can allow for a water temperature sustained within an acceptable range without the need for the operation of a cooling tower or boiler. This operational mode also reduces pump energy needed to circulate the water through the larger equipment.

The advantages of WSHP systems go beyond energy savings. WSHPs are commonly interior to the building and smaller in size allowing them to be located in either a ceiling plenum or a small mechanical room preserving floor space for other needs. A WSHP can serve a single room or be ducted to heat/cool multiple rooms with a dedicated thermostat within the space, allowing for individual zone control. This enables a high level of occupant control and satisfaction. The fact that there are multiple WSHPs within a building reduces the risk associated with unit malfunction or total system failure compared to a large, centralized unit that serves a large portion of or the entire building. As with all HVAC equipment, proper maintenance is critical to maintaining its rated efficiency, ensuring correct operation, and extending the life of the equipment.

WSHP Products by AAON

AAON offers high-quality, energy-efficient WSHP equipment although these units do not conform with the most traditional definition of a WSHP. Much of the industry thinks of the WSHP described above, small horizonal units located in the ceiling plenum with ducted connections to the space it conditions, but AAON has expanded the opportunity for using WSHP technology.

AAON rooftop units can be configured to use WSHP technology and be tied to the same water loop as the interior units. These units are especially appropriate for larger spaces in the commercial settings, such as open office areas, conference rooms, or large gathering spaces. These units can be used for heating and cooling as well as condition up to 100% outside air to meet ventilation needs. Energy recovery wheels, variable speed fans, and variable capacity compressors are all selections that can increase the efficiency of these units

AAON also offers indoor self-contained WSHP units up to 70 tons capacity that can be connect to the same water loop as other water source heat pumps within the building. An indoor self-contained WSHP unit employing WSHP technology replaces a central air handling unit in a system while taking advantage of the associated water source heat pump efficiencies. These units are located in a mechanical room with ductwork being routed to the rooms served. Ventilation can also be provided with an attached mixing box with modulating economizers.

With customizable options and industry-leading performance, AAON systems deliver comfort, flexibility, efficiency, and reliability to meet every building’s needs.

Frequently Asked Questions (FAQs) About Water-Source Heat Pumps (WSHP)

What is WSHP in HVAC?

A WSHP is an HVAC unit that heats and cools air using the heat pump direct expansion cycle with water as the means of absorbing and rejecting heat. Most commonly a WSHP references a unit connected to a heat pump water loop that incorporates a boiler and a cooling tower to act as the heat source or sink. A ground source (sometimes called a geothermal) heat pump is a type of WSHP, except it uses the ground as the heat source or sink instead of the cooling tower and boiler.

A heat pump when cooling is comparable in efficiency to other cooling equipment, but when heating they are the most efficient technology, even better than a 100% efficient electric resistance heating coil. When multiple WSHPs are connected to a single heat pump water loop this efficiency is further enhanced because heat can be transferred between spaces decreasing or eliminating the need for the heat source or sink.

For this reason, WSHPs are an excellent solution in commercial HVAC applications, especially as the industry progresses towards electrification.

How does a WSHP work?

WSHPs have an internal direct expansion (DX) refrigeration cycle that does the work of heating or cooling air that is delivered to the space. This DX cycle either absorbs or rejects heat via a water loop that connects all the units in the system together. This loop temperature is maintained by the heat source (boiler) and heat sink (cooling tower).

-

Heating Mode: Heat is extracted from the water loop.

-

Cooling Mode: Heat is rejected to the water loop.

What is the difference between a WSHP and a geothermal heat pump?

The key difference is the heat source and heat sink in the system:

-

WSHP uses a water loop that is connected to a cooling tower and boiler.

-

Ground Source (Geothermal) Heat Pump routes the water loop through the ground, leveraging stable underground temperatures.

What are the key benefits of using a WSHP?

-

Exceptional energy efficiency

-

Lower operating costs compared to traditional HVAC systems

-

Environmentally friendly with reduced carbon footprint

How do WSHP systems compare to Air Source Heat Pumps (ASHP)?

-

Location: ASHP are located outside.

-

Efficiency: WSHPs are more efficient due to water’s superior heat transfer properties.

-

Applications: WSHPs are commonly used in buildings consisting of multiple thermal zones.

-

Weather Dependence: WSHPs capacity and performance are less affected by outdoor temperatures compared to ASHPs.

Why choose AAON for your WSHP needs?

AAON offers high-quality, energy-efficient WSHP equipment, although AAON units do not conform with the most traditional definition of a WSHP. Much of the industry thinks of the WSHP as small horizontal units located in the ceiling plenum, but AAON has expanded the opportunity to incorporate WSHP technology. AAON manufacturers WSHPs ranging from a half-ton to 240-tons capacity that can be located inside the building or placed on the roof with the ability to condition 100% outdoor air. With customizable options and industry-leading performance, AAON systems deliver comfort, flexibility, efficiency, and reliability to meet every building’s needs.

Discover the Power of Water-Source Heat Pump Efficiency.

AAON’s line of water-source heat pumps delivers energy savings, reliability, and flexible design options for commercial applications.

Click Here to learn more about AAON WSHPs.