Compressor technologies are the driving force behind the efficient operation of Heating, Ventilation, and Air Conditioning (HVAC) systems.

Understanding the various compressor technologies used in HVAC is crucial for optimizing system performance, energy efficiency, and overall comfort in buildings. In this article, we explore the different compressor technologies commonly employed in HVAC systems.

On/Off Scroll Compressors:

On/off scroll compressors are known for their high full-load efficiencies, often expressed in terms of Energy Efficiency Ratio (EER). However, they fall short in providing precise temperature and humidity control. These compressors employ a straightforward control mechanism, making them suitable for systems with only a few compressors. In larger systems, multiple stages of capacity control can be implemented, improving their versatility.

Advantages: Low first cost, Simple control

Two-Stage Scroll Compressors:

Two-stage scroll compressors offer a compelling combination of simplicity and efficiency. They inherit the staged capacity control approach, akin to on/off scroll compressors, while delivering part-load efficiencies comparable to variable speed compressor systems. By integrating dual two-stage compressors, systems can incorporate up to five stages of capacity control.

The unique feature of two-stage compressors is their ability to switch between part-load and full-load capacity settings. This transition is facilitated by two internal bypass ports that allow the compressor to operate at partial capacity when the demand for cooling or heating is lower. In such instances, a mechanical ring is pressure-activated to seal the bypass ports, instantly shifting capacity to 100%. This capability to run the system for longer periods at part-load capacity can effectively reduce indoor humidity.

Advantages: High part load efficiency (IEER), Simple control (no modulating signal)

Digital Scroll Compressors:

Digital scroll compressors, also referred to as 10-100% variable capacity scroll compressors, are at the forefront of applications demanding precise control over temperature and humidity. They find their niche in critical environments like hospitals, museums, and data centers.

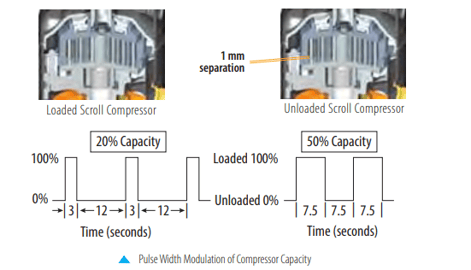

The digital scroll compressor requires a 1-5 VDC control signal to control 10-100% compressor capacity modulation. A solenoid unloader valve is responsible for modulating capacity, controlled by the input signal. In an unloaded state, the scroll elements separate, resulting in 0% capacity and minimal power consumption, as the compressor motor rotates freely.

To illustrate, during a 15-second cycle, the compressor may operate loaded for 3 seconds and unloaded for 12 seconds, achieving a 20% capacity in the first scenario. In the second scenario, a 50% capacity is attained by operating loaded for 7.5 seconds and unloaded for 7.5 seconds. The cyclical loading and unloading, accomplished via Pulse Width Modulation, not only reduces capacity but also leads to significant energy savings. Additionally, these compressors excel in oil return due to the continuous flow of refrigerant during the loaded state.

Advantages: Good efficiency (IEER), Best turndown at 10%, Precise control of discharge air temperature

Variable Speed Scroll Compressors:

Variable speed scroll compressors stand out with the highest part-load efficiencies among all compressor technologies. They excel in delivering precise control over both temperature and humidity in HVAC systems.

These compressors achieve capacity modulation through speed control. A Variable Frequency Drive (VFD) is essential for changing the speed of the inverter-duty compressor. The VFD alters the frequency (measured in Hz), which correlates to a change in speed (measured in rpm). To ensure safe and efficient operation, variable speed compressors necessitate specific controls that enforce the compressor's operating limits.

An electronic expansion valve is a vital component of the refrigerant circuit when incorporating variable speed scroll compressors, as these compressors operate within a wide capacity range. To maintain oil return to the compressor, flush cycles become necessary as capacity decreases, thereby ensuring stable operation. Advanced refrigeration system controls are also a prerequisite for minimizing these flush cycles and ensuring consistent control.

Advantages: Highest efficiency (IEER), Complex controls but offers a lot of adaptability for a wide range of environmental conditions

Digital Scroll + Two-Stage Scroll Compressors:

The combination of Digital scroll and Two-Stage scroll compressors presents a synergy of high part-load efficiency and precise temperature and humidity control. The Digital scroll component is responsible for maintaining precise supply air temperature, while the Two-Stage compressor complements it by staging on and off as needed.

Advantages: High efficiency (IEER), High turndown (minimum equal to a Dual digital system), Precise control, Less complex than a dual digital system

Conclusion:

In the world of HVAC compressor technologies, choices abound to meet diverse needs, from maximizing energy efficiency to providing optimal control over indoor environmental conditions. Understanding the nuances of each compressor type empowers system designers and building managers to select the most suitable technology for their specific requirements, ensuring efficient, comfortable, and sustainable indoor environments.