Indoor Agriculture

Get growing with reliable indoor agriculture HVAC solutions and reap the benefits of consistent environmental control.

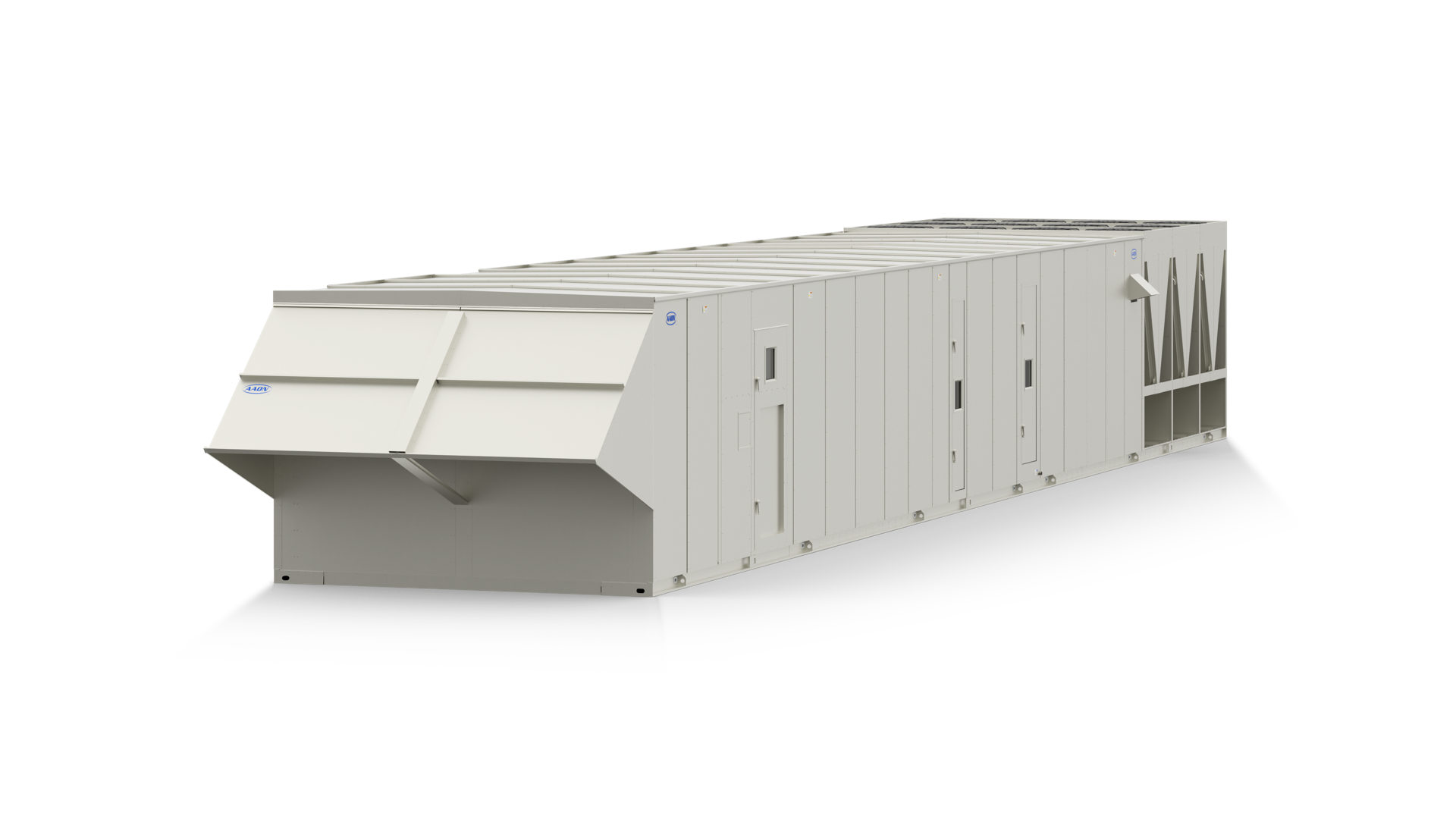

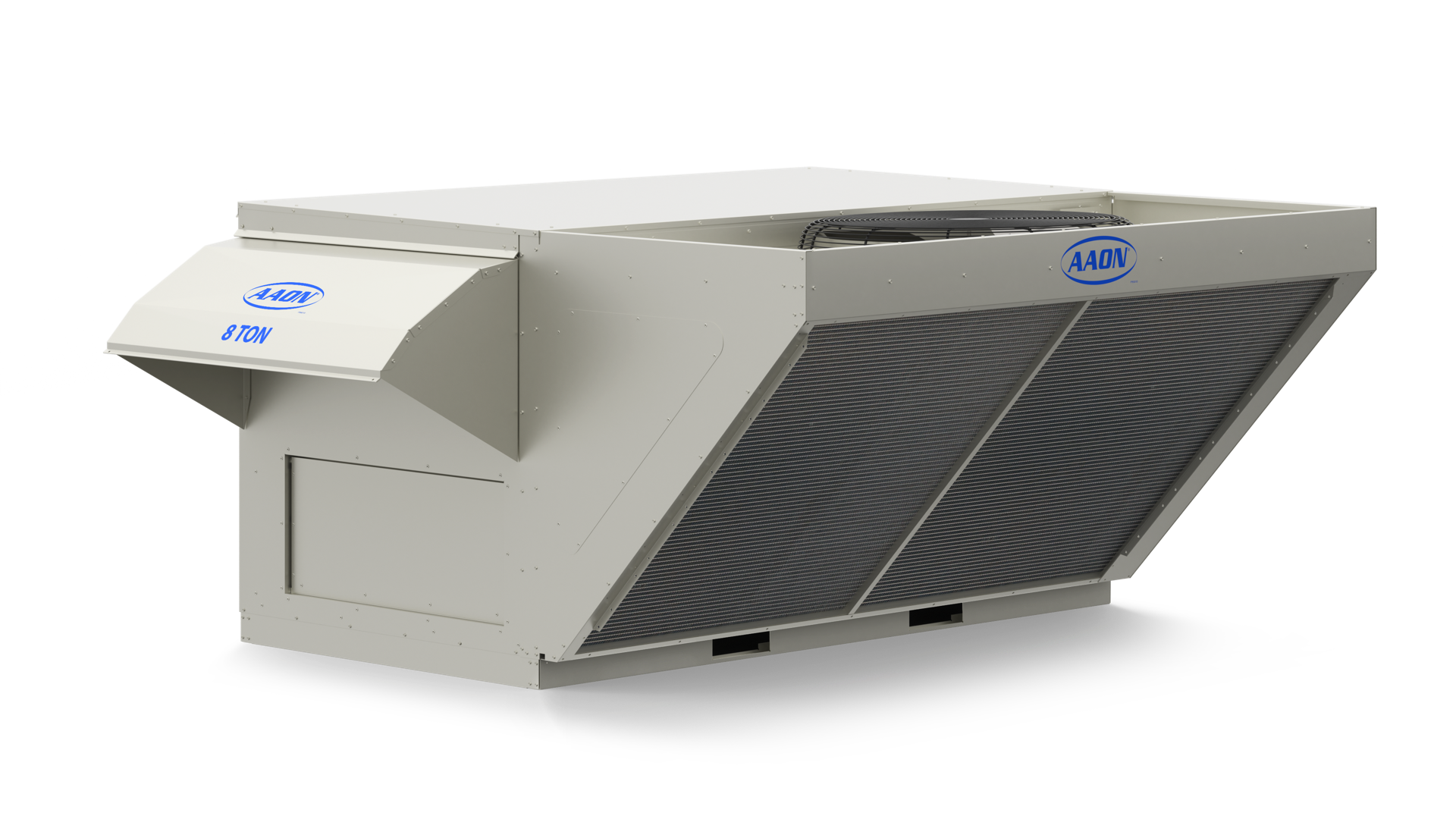

AAON Grow equipment is specially designed for the toughest indoor agriculture challenges. Achieve full control for each phase of development to yield true energy efficiency and operational cost containment.

INDOOR AGRICULTURE SOLUTIONS

-

About Indoor Agriculture

Indoor agriculture buildings require precise control over lighting, temperature, and humidity levels, which can be energy-intensive and impact operational costs. Some of the key HVAC challenges indoor agriculture facilities face include:

- Maintaining consistent temperature and humidity levels within the grow space to promote optimal plant growth and prevent disease.

- Proper ventilation and air circulation are also crucial to ensure carbon dioxide levels remain at adequate levels and to prevent the buildup of harmful gasses like ethylene.

- Managing the heat generated by grow lights, which can significantly increase the indoor temperature. The HVAC system must be designed to handle the additional heat load to prevent overheating and protect the plants.

- Air quality and cleanliness of the grow space. Dust, mold, and other contaminants can negatively impact plant growth and introduce health risks to workers. Mold and fungus can damage crops and impact the profitability of a grow house.

-

Indoor Agriculture Considerations

When implementing HVAC solutions in an indoor agriculture facility, here are some key considerations to keep in mind:

Temperature and Humidity Control

Since indoor agriculture involves growing crops in a controlled environment, it is important to maintain a consistent temperature and humidity level to optimize plant growth. HVAC systems must be designed to provide precise control of these parameters and maintain them within a narrow range.

Air Filtration

The air quality within indoor agriculture buildings is critical to maintaining plant health and preventing disease. HVAC systems must be equipped with high-efficiency air filters to remove airborne contaminants such as dust, mold, and bacteria.

CO2 and Oxygen Control

Plants require a certain level of carbon dioxide (CO2) and oxygen to grow properly. HVAC systems must be designed to provide proper air exchange rates to maintain the correct levels of these gasses within the growing area.

Energy Efficiency

Indoor agriculture buildings require a significant amount of energy to maintain optimal growing conditions. HVAC systems must be designed with energy efficiency in mind to minimize operating costs.

System Reliability

In the event of an HVAC system failure, crops can quickly become compromised. It is important to design systems with redundant components to ensure that the environment remains stable in the event of an equipment failure. -

Indoor Agriculture Solutions

The HVAC products recommended for indoor agriculture may vary based on the type of facility. Some HVAC products that are recommended for these facilities may include:

High-efficiency HVAC systems

Indoor agriculture requires precise control over temperature, humidity, and ventilation to ensure optimal plant growth. High-efficiency HVAC systems can help maintain consistent and precise environmental conditions while also reducing energy consumption and operating costs.

Dehumidifiers

Plants release moisture into the air, which can lead to high humidity levels that can promote mold and mildew growth and damage the building structure. Dehumidifiers can help regulate humidity levels and prevent excess moisture from causing problems. Many grow houses use stand alone dehumidifiers. However, these units do not necessarily achieve the desired goal and can actually make the HVAC perform poorly. Ideally, you want your dehumidification to be handled by your rooftop or split system.

Air filtration systems

Indoor agriculture facilities need to maintain a clean and healthy environment to promote plant growth and prevent the spread of diseases. Air filtration systems can help remove dust, pollen, mold spores, and other contaminants from the air, improving air quality and preventing plant diseases.

- Maintaining consistent temperature and humidity levels within the grow space to promote optimal plant growth and prevent disease.

- Proper ventilation and air circulation are also crucial to ensure carbon dioxide levels remain at adequate levels and to prevent the buildup of harmful gasses like ethylene.

- Managing the heat generated by grow lights, which can significantly increase the indoor temperature. The HVAC system must be designed to handle the additional heat load to prevent overheating and protect the plants.

- Air quality and cleanliness of the grow space. Dust, mold, and other contaminants can negatively impact plant growth and introduce health risks to workers. Mold and fungus can damage crops and impact the profitability of a grow house.

When implementing HVAC solutions in an indoor agriculture facility, here are some key considerations to keep in mind:

Temperature and Humidity Control

Since indoor agriculture involves growing crops in a controlled environment, it is important to maintain a consistent temperature and humidity level to optimize plant growth. HVAC systems must be designed to provide precise control of these parameters and maintain them within a narrow range.

Air Filtration

The air quality within indoor agriculture buildings is critical to maintaining plant health and preventing disease. HVAC systems must be equipped with high-efficiency air filters to remove airborne contaminants such as dust, mold, and bacteria.

CO2 and Oxygen Control

Plants require a certain level of carbon dioxide (CO2) and oxygen to grow properly. HVAC systems must be designed to provide proper air exchange rates to maintain the correct levels of these gasses within the growing area.

Energy Efficiency

Indoor agriculture buildings require a significant amount of energy to maintain optimal growing conditions. HVAC systems must be designed with energy efficiency in mind to minimize operating costs.

System Reliability

In the event of an HVAC system failure, crops can quickly become compromised. It is important to design systems with redundant components to ensure that the environment remains stable in the event of an equipment failure.

The HVAC products recommended for indoor agriculture may vary based on the type of facility. Some HVAC products that are recommended for these facilities may include:

High-efficiency HVAC systems

Indoor agriculture requires precise control over temperature, humidity, and ventilation to ensure optimal plant growth. High-efficiency HVAC systems can help maintain consistent and precise environmental conditions while also reducing energy consumption and operating costs.

Dehumidifiers

Plants release moisture into the air, which can lead to high humidity levels that can promote mold and mildew growth and damage the building structure. Dehumidifiers can help regulate humidity levels and prevent excess moisture from causing problems. Many grow houses use stand alone dehumidifiers. However, these units do not necessarily achieve the desired goal and can actually make the HVAC perform poorly. Ideally, you want your dehumidification to be handled by your rooftop or split system.

Air filtration systems

Indoor agriculture facilities need to maintain a clean and healthy environment to promote plant growth and prevent the spread of diseases. Air filtration systems can help remove dust, pollen, mold spores, and other contaminants from the air, improving air quality and preventing plant diseases.

Why AAON for Indoor Agriculture?

AAON stops at nothing to design the very best.

All AAON products are highly configurable and designed to optimize your exact environment. With high quality features, our systems set the industry standard for long-lasting quality.

AAON equipment is easy to access and convenient to work on.

Our products make it simple for technicians to service our units efficiently and affordably. Unique features like color-coded wiring and full height stainless steel door hinges are designed with serviceability in mind.

Our products are tested for all functions and receive a unit-specific report before they leave the factory.

Choose cutting-edge engineering that pushes the boundaries of what's possible in virtually any climate and application. AAON units have been rigorously tested and verified in the lab to ensure optimal performance is delivered in the field.

Dare us to exceed expectations.

Regardless of the challenge, AAON has the capabilities to fulfill project requirements and deliver long-term value to customers. Contact an AAON Representative to learn how our products serve as your solutions.