Cleanroom Environments

BASX provides maximized cleanroom solutions for efficiency and effectiveness with industry-leading engineering.

BASX, powered by AAON, delivers on optimizing, strict control of cleanroom environments for various industries ranging from semiconductor manufacturing to hospital environments. Discover customized cleanroom solutions that won’t compromise your controlled environment.

BASX CLEANROOM INDUSTRY SOLUTIONS

-

About Cleanrooms

BASX designs specialized HVAC and filtration systems to minimize the introduction of contaminants and are used in various industries such as manufacturing, pharmaceuticals, biotechnology, medical devices, aerospace and more. Cleanroom controlled environments are designed to maintain low levels of airborne particles such as dust, Volatile Organic Compounds (VOC), bacteria, and other contaminants. BASX offers ISO classes 1-8.

-

Cleanroom HVAC Considerations

Challenges that cleanroom environments face include maintaining a high level of air quality, controlling temperature and humidity, and prevention of cross-contamination.

Effective air filtration system

BASX cleanroom systems are designed with specialized air filtration that can remove particles as small as 0.3 microns and provide sufficient air exchange per hour to maintain the required level of cleanliness.

Effective air temperature and humidity controls

BASX cleanroom systems provide strict temperature and humidity control and maintain a stable and uniform environment.

Effective airflow control

BASX cleanroom systems are carefully controlled to prevent the introduction of contaminants and are custom designed to provide directional laminar airflow and prevent the buildup of stagnant air. -

Cleanroom HVAC Solutions

BASX has the experience you can count on to deliver cost-effective solutions that are energy efficient and maximize cleanroom effectiveness. With over 25 years experience in custom cleanroom design systems and manufacturing for some of the most important bio-pharmaceutical, semiconductor and medical device companies in the world, BASX offers a wide range of custom designed solutions to meet your cleanroom environment specifications. With a BASX system, you can count on maximum cleanroom effectiveness for Grade A and B, ISO-3 to ISO-8, and Class 1 to 100,000 environments.

BASX Cleanroom Products:

- Modular Cleanrooms - Truly modular design with ultimate flexibility in materials and configurations to meet performance and budget requirements.

- Grid Systems – Walkable ceiling systems available as Top or Bottom-load, and as stainless steel or aluminum construction.

- Plenum Modules - Eliminates the need for ductwork while reducing the overall static pressure and are ideal for confined ceiling spaces with no available ducting to a remote fan or air handler.

- Ceiling Systems – Options include: Flush Ceiling Systems with a Top or Bottom-Load or Flush ceiling system.

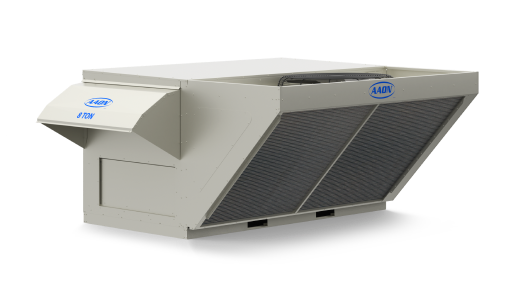

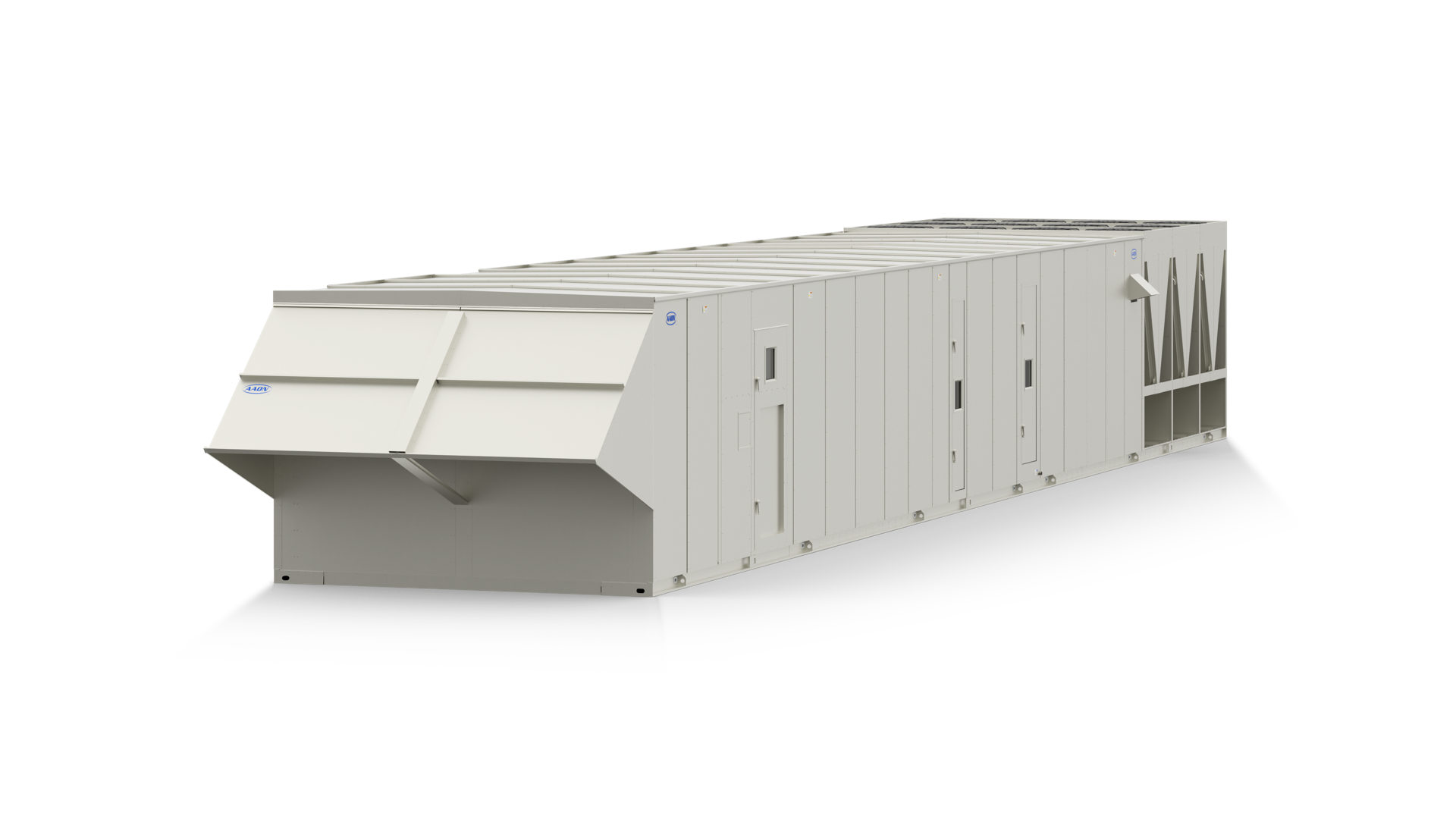

- Air Handling Units – Products include: Recirculating Air Handling Units, Make up Air Handling Units and Fan Filter Units

- Medical Applications – Customized HVAC units are designed to reduce operational costs by lowering energy consumption with increased efficiency.

-

BASX iOR Product Line

BASX revolutionized surgical theaters by taking the same basic cleanroom designs and incorporated them into surgical environments. Operating rooms must be designed to maintain strict temperature control, humidity control, filtration and room pressure as well as control the contamination of airborne particles such as solids, liquids, gases and other organic or non-organic matter.

Hybrid Operating Rooms

BASX plenum systems are designed to integrate state-of-the-art medical imaging devices and other necessary equipment used in minimally invasive surgical suites. Design considerations must account for varying conditions and zones within hospitals using customized controls geared for preventing the spread of infectious diseases.

iOR Diffusion System

BASX iOR surgical room diffusers are designed with architects, MEP contractors, surgeons and most importantly patients in mind. Benefits of the integrated modular design include 50-70% reduction of install time, integrated lights, boom mounts, air balance, and patient safety by reducing risk of Healthcare Associated Infections (HAIs) from improved laminar air over operating table.

Designed with Efficiency

HVAC and air quality is one of the most expensive operational costs to hospitals. Energy usage, along with air quality, must be balanced. Different methods of conserving energy can be implemented using a variety of systems to economize air and water and attempt to recover energy in the most efficient way.

BASX designs specialized HVAC and filtration systems to minimize the introduction of contaminants and are used in various industries such as manufacturing, pharmaceuticals, biotechnology, medical devices, aerospace and more. Cleanroom controlled environments are designed to maintain low levels of airborne particles such as dust, Volatile Organic Compounds (VOC), bacteria, and other contaminants. BASX offers ISO classes 1-8.

Challenges that cleanroom environments face include maintaining a high level of air quality, controlling temperature and humidity, and prevention of cross-contamination.

Effective air filtration system

BASX cleanroom systems are designed with specialized air filtration that can remove particles as small as 0.3 microns and provide sufficient air exchange per hour to maintain the required level of cleanliness.

Effective air temperature and humidity controls

BASX cleanroom systems provide strict temperature and humidity control and maintain a stable and uniform environment.

Effective airflow control

BASX cleanroom systems are carefully controlled to prevent the introduction of contaminants and are custom designed to provide directional laminar airflow and prevent the buildup of stagnant air.

BASX Cleanroom Products:

- Modular Cleanrooms - Truly modular design with ultimate flexibility in materials and configurations to meet performance and budget requirements.

- Grid Systems – Walkable ceiling systems available as Top or Bottom-load, and as stainless steel or aluminum construction.

- Plenum Modules - Eliminates the need for ductwork while reducing the overall static pressure and are ideal for confined ceiling spaces with no available ducting to a remote fan or air handler.

- Ceiling Systems – Options include: Flush Ceiling Systems with a Top or Bottom-Load or Flush ceiling system.

- Air Handling Units – Products include: Recirculating Air Handling Units, Make up Air Handling Units and Fan Filter Units

- Medical Applications – Customized HVAC units are designed to reduce operational costs by lowering energy consumption with increased efficiency.

BASX revolutionized surgical theaters by taking the same basic cleanroom designs and incorporated them into surgical environments. Operating rooms must be designed to maintain strict temperature control, humidity control, filtration and room pressure as well as control the contamination of airborne particles such as solids, liquids, gases and other organic or non-organic matter.

Hybrid Operating Rooms

BASX plenum systems are designed to integrate state-of-the-art medical imaging devices and other necessary equipment used in minimally invasive surgical suites. Design considerations must account for varying conditions and zones within hospitals using customized controls geared for preventing the spread of infectious diseases.

iOR Diffusion System

BASX iOR surgical room diffusers are designed with architects, MEP contractors, surgeons and most importantly patients in mind. Benefits of the integrated modular design include 50-70% reduction of install time, integrated lights, boom mounts, air balance, and patient safety by reducing risk of Healthcare Associated Infections (HAIs) from improved laminar air over operating table.

Designed with Efficiency

HVAC and air quality is one of the most expensive operational costs to hospitals. Energy usage, along with air quality, must be balanced. Different methods of conserving energy can be implemented using a variety of systems to economize air and water and attempt to recover energy in the most efficient way.

Why choose BASX?

All BASX products are highly configurable.

All BASX products are designed to optimize your environmental needs with high quality features for systems that set the industry standard for long-lasting quality.

HVAC and air quality is one of the most expensive operational costs.

Energy along with air quality must be balanced. Different methods of conserving energy can be implemented using a variety of systems to economize air and water and attempt to recover energy in the most efficient way.

Based on levels of importance and capacity for individual facilities, designs can be custom built to accommodate energy conservation and efficiency. Choosing the right equipment through customization can have very short payback periods. Turn to BASX for highly experienced HVAC engineers who can design systems to your unique requirements.

From beginning to end.

Cleanroom Solutions

With over 25 years in custom cleanroom design and manufacturing for some of the most important bio-pharmaceutical, semiconductor and medical device companies in the world, BASX Solutions has the experience you can count on to deliver cost-effective solutions that are energy efficient and maximize cleanroom effectiveness.

BASX Solutions offers a wide range of custom designed solutions to meet your cleanroom environment specifications.

Choose BASX for cutting-edge engineering that pushes the boundaries of what's possible in virtually any climate or application.

Our innovative team will provide support from design all the way through to installation.