Grow Units

Harvest in more ways than one. Grow unit solutions that increase production while reducing energy consumption.

Optimal conditions create a quality product. With AAON, you can maximize your yield with conditions that adapt to plant phase specifications while minimizing energy consumption.

Indoor Agriculture

-

About Grow Units

Grow rooms or indoor cultivation facilities, are controlled environments designed for indoor cultivation of plants, particularly for horticultural purposes. Grow units provide a controlled climate, including temperature, humidity, lighting, and ventilation, to create an optimal environment for plant growth.

-

The Challenge

Maintaining optimal temperature and humidity levels is crucial for plant growth and health. Grow units often require precise control of these parameters to create an ideal growing environment. Variations in temperature and humidity can lead to plant stress, disease, or reduced yields.

-

The Solution

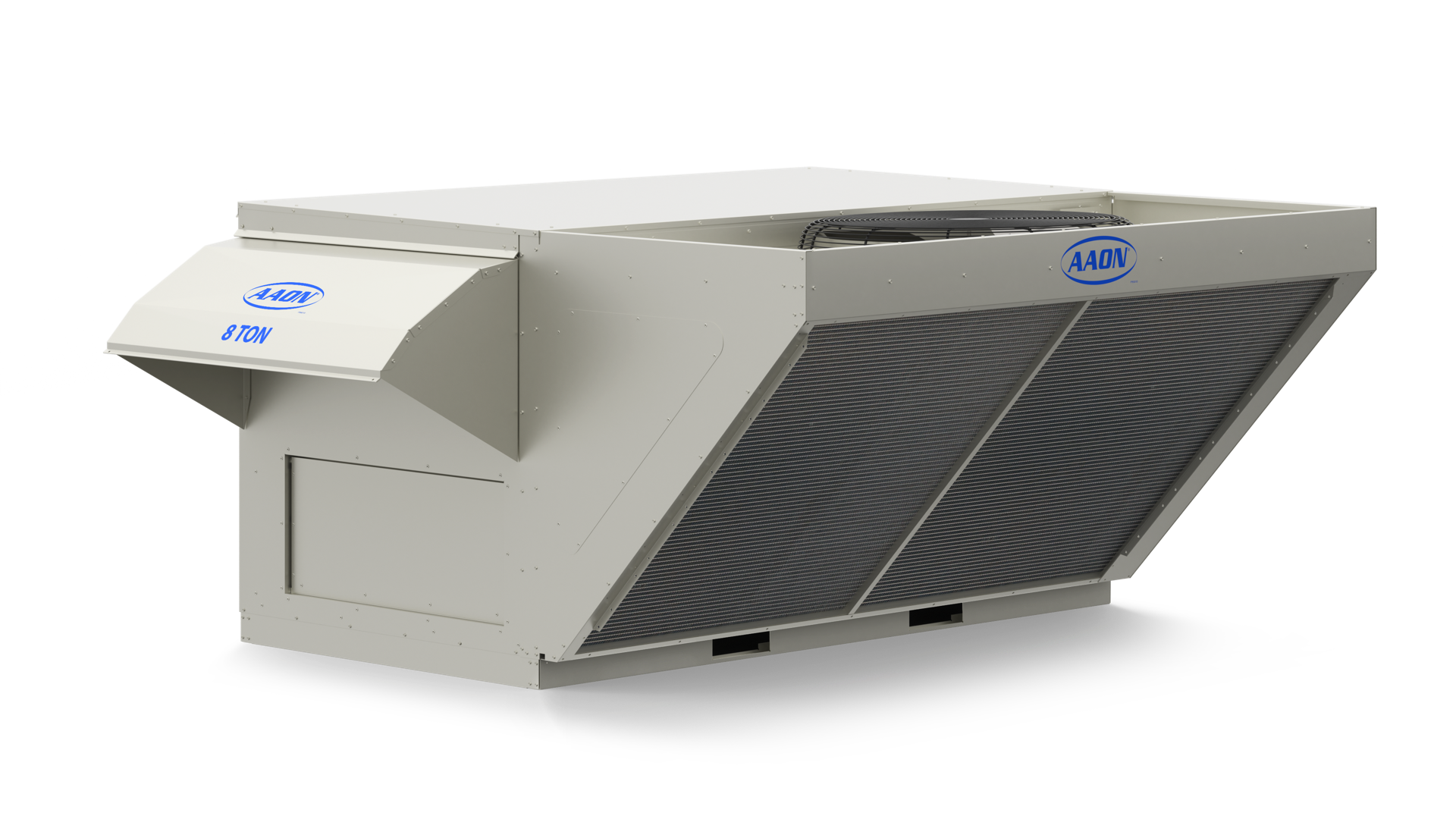

Addressing HVAC challenges in grow units is possible with careful system design, integration of specialized equipment such as dehumidifiers, air filtration systems, and precise environmental controls. With AAON, you can expect solutions that adapt to the needs of your plant production process. Solutions such as:

- Temperature and humidity control for various stages of plant growth with control mode operations such as Off Mode, Grow Mode, Dry Mode, Fan Mode, Cool Mode, Heat Mode, and Purge Mode

- Digital compressors for sensible load control.

- Modulating hot gas reheat for maintaining humidity levels that promote healthy plant growth.

- Low ambient controls for cooling and humidity control year-round.

- Multiple filtration configurability for clean air.

Grow rooms or indoor cultivation facilities, are controlled environments designed for indoor cultivation of plants, particularly for horticultural purposes. Grow units provide a controlled climate, including temperature, humidity, lighting, and ventilation, to create an optimal environment for plant growth.

Maintaining optimal temperature and humidity levels is crucial for plant growth and health. Grow units often require precise control of these parameters to create an ideal growing environment. Variations in temperature and humidity can lead to plant stress, disease, or reduced yields.

Addressing HVAC challenges in grow units is possible with careful system design, integration of specialized equipment such as dehumidifiers, air filtration systems, and precise environmental controls. With AAON, you can expect solutions that adapt to the needs of your plant production process. Solutions such as:

- Temperature and humidity control for various stages of plant growth with control mode operations such as Off Mode, Grow Mode, Dry Mode, Fan Mode, Cool Mode, Heat Mode, and Purge Mode

- Digital compressors for sensible load control.

- Modulating hot gas reheat for maintaining humidity levels that promote healthy plant growth.

- Low ambient controls for cooling and humidity control year-round.

- Multiple filtration configurability for clean air.

Grow Units Applications

Grow units are commonly used for various applications related to plant cultivation. Some common applications of grow units include:

Indoor Agriculture

Grow units are utilized for indoor farming and cultivation of various crops, such as cannabis, leafy greens, herbs, microgreens, vegetables, and fruits. Indoor agriculture allows for year-round cultivation regardless of external weather conditions and provides a controlled environment that can optimize plant growth and maximize production.

Research and Development

Grow units are employed in research institutions, universities, and agricultural facilities for conducting experiments, studies, and breeding programs. Researchers can manipulate and monitor various environmental factors to study plant responses, optimize growth conditions, and develop new cultivation techniques.

Plant Propagation

Grow units are used for the propagation of plants through techniques like cloning, tissue culture, and seed germination. The controlled environment provides an ideal setting for the initial growth stages of plants, ensuring high survival rates and healthy development before they are transplanted to larger growing areas.

Urban Farming

Grow units are employed in urban farming initiatives, where space is limited and traditional agriculture may not be feasible. Vertical farms, rooftop gardens, and container-based cultivation systems make use of grow units to grow crops in urban settings, contributing to local food production and reducing the need for long-distance transportation.

Specialty Crop Cultivation

Grow units can be utilized for the cultivation of specialty crops with specific environmental requirements. This includes plants with unique temperature, humidity, or light requirements, as well as plants that are sensitive to pests or diseases and benefit from a controlled indoor environment.

These applications highlight the versatility of grow units in enabling controlled and efficient plant cultivation in a variety of contexts. By providing a controlled environment, growers can optimize growth conditions, increase yields, reduce crop losses, and achieve consistent product quality.

Key Considerations for Grow Units

Maintaining optimal temperature and humidity levels is crucial for plant growth in grow units.

HVAC systems should be designed to provide precise temperature and humidity control, ensuring that the conditions are within the desired range for the specific plant species being cultivated. This may involve the use of heating, cooling, and dehumidification equipment, as well as humidifiers or misting systems

Proper air circulation and ventilation are essential for controlling carbon dioxide levels, removing excess heat, and preventing the buildup of stale air and potential issues like mold or pathogens.

HVAC systems should incorporate ventilation systems with fans or blowers to ensure adequate air exchange and distribution throughout the grow unit. Consideration should also be given to air filtration to remove contaminants and maintain air quality.

Energy efficiency is an important consideration for the sustainability and cost-effectiveness of grow units.

HVAC systems should be designed with energy-efficient components and technologies, such as variable frequency drives (VFDS) for fans or pumps, to optimize energy usage. Implementing controls and automation systems can help monitor and adjust HVAC operations based on real-time environmental conditions and plant requirements, further enhancing energy efficiency.

Grow units located in residential or commercial areas may need to address concerns related to sound and odor emissions.

HVAC systems should be designed with sound reduction features, such as insulated ductwork to minimize sound pollution. Additionally, odor control mechanisms such as carbon filters or scrubbers can be integrated into the HVAC system to mitigate any strong or undesirable odors associated with the cultivation process.

These considerations should be tailored to the specific requirements of the grow unit, taking into account factors such as the size of the operation, plant types, and local climate conditions. Engaging with experienced HVAC professionals familiar with indoor cultivation can help design and implement an effective HVAC system that meets the unique needs of the grow unit while ensuring optimal plant growth and productivity.

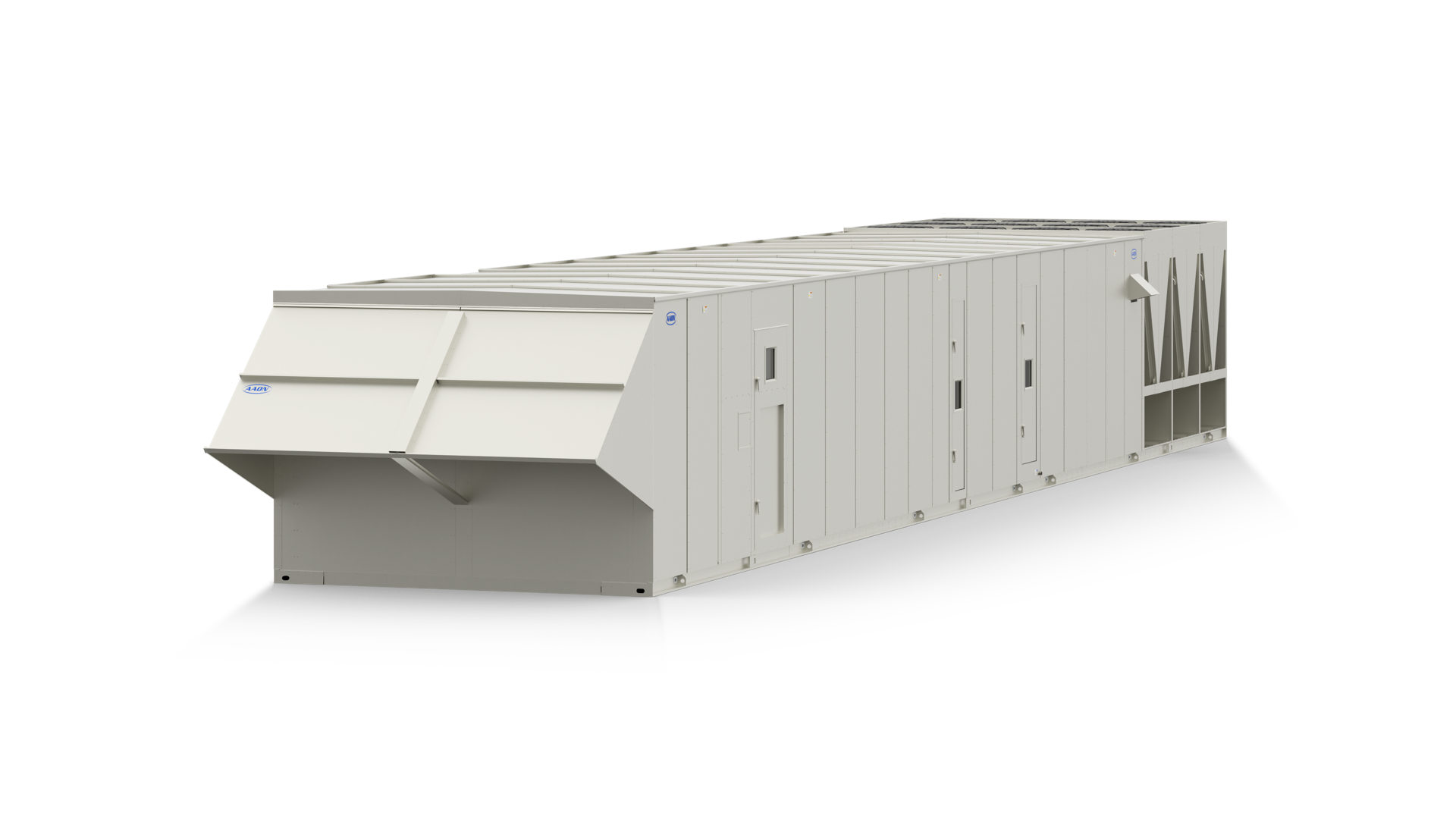

All AAON HVAC products are highly configurable and designed to optimize your exact environment with cutting-edge engineering to push the boundaries in virtually any setting.

AAON stops at nothing to design the very best. Our systems set the industry standard for longevity and low cost of ownership.

AAON equipment is easy to access and convenient to work on. Our award-winning cabinet designs make it simple for technicians to service our units efficiently and affordably.

AAON HVAC units offer easy start-up and renowned reliability. Our products are tested for all functions and receive a unit-specific report before they leave the factory.

Related Products

Dare us to exceed expectations.

Regardless of the challenge, AAON has the capabilities to fulfill project requirements and deliver long-term value to customers. Contact an AAON Representative to learn how our products serve as your solutions.